01 The 3rd Generation

High Efficiency Precision

Injection Molding Machine

Universe Serial

- |

02 Various Plastic Products

Made By Injection Machines

-

-

- |

03 Injection Machines

Space Between Tie Bars,

Clamping Force

Euromap Standard Injection Unit

Shot Weight, Power System,

Electric Control System |

Manufacture:

High Quality, High Efficient, High Precision and Energy Saving, All are the purpose for each of us!

Design:

Reliable, Long Life, Modular, and User Friendly, are our guiding ideology for each of designers.

Sales:

Creating Value for Customers and Providing Cost-Effective Solution, are the action rules for each of salesman.

Service:

Fast, High Efficient, Round-the-Clock Customer Service, are the standards for each of service engineer.

|

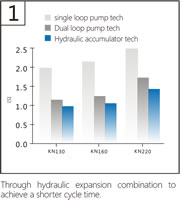

04 Injection Machines

Hydraulic Accumulator Tech

Hydraulic Expansion Combination

Shorter Cycle Time |

05 Hydraulic Accumulator Tech

High Performance/Price Ratio

-

- |

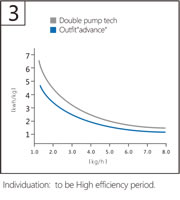

06 Outfit Advance

High Efficiency Period

-

- |

| Through hydraulic expansion combination to achieve a shorter cycle time. |

High performance-price ratio satisfies the requirements of different customers. |

Individuation: To be high efficiency period. |

07 Position Regulate Screw PRS

Accurate Shot Weight

Repetition Precision |

08 Reliability High Response

Double Deck Injection Unit

- |

|

| Repetition Precision: To achieve accurate shot weight through PRS function |

Reliability: High response double-deck injection unit |

|

Wide Range Application:

The Universe Serial injection molding machine can accommodate all known injection molding processes. With the powerful control system, it can be seamlessly integrated with different peripheral equipments. The complete set of plastic injection molding solutions can actualize the special production process, so it can have wide range applications. Such as ARIMOULD, AQUAMOULD, CELLMOULD, IML, IMD, PIM, OVERMOLDING, Super Thick-Wall Molding, Muti-Components Tech, Multi Process Combination

High Performance/Price Ratio:

The Universe injection molding machine inherits the original Japanese design and high-quality manufacturing technology and it's assembled in China. So it has the High performance-price ratio.

Individuation:

According to the customer's choice and actual demand, optimize the combination of clamping, injection and driver unit to satisfied

all the requirements of customers and it's also keep high efficiency.

High Repetition Precision:

Universe serial injection molding machine optimizes injection process, guarantees repeated filling and consistent high-quality injection. Screw position control function, can achieve the similar injection precision of Full-Electric injection machine.

Reliability:

Universe serial injection molding machine uses the high-quality components. It can

work efficiently for a long time. Strong and durable, needn't the frequent maintenance. Advantages:

- High response double-deck injection unit

- High rigid four-column guide clamping unit

- Special surface treatment of mechanical parts

|

| Functions |

UN100-400EPIII |

UN500-950EPIII |

UN1250-1850EPIII |

| Injection Unit |

| Bi-Metal Screw: B\C\D screw |

Standard |

Standard |

Standard |

| Chromium Screw: A Screw |

Standard |

Standard |

Standard |

| Bi-Metal Screw&Barrel |

Option |

Option |

Option |

| Full Hard Screw |

Option |

Option |

Option |

| High Wear Resistance and Corrosion Resistance Screw&Barrel |

Option |

Option |

Option |

| Needle Shut-Off Nozzle |

Option |

Option |

Option |

| Hydraulic/Air Shut-Off Nozzle |

Option |

Option |

Option |

| Balanced Dual Cylinder Injection Unit |

Standard |

Standard |

Standard |

| Balanced Dual Cylinder Carriage Unit |

Standard |

Standard |

Standard |

| High Rigid Double Layer Injection System |

Standard |

Standard |

Standard |

| Injection Unit Increase&Decrease |

Option |

Option |

Option |

| Hydraulic Motor Increase |

Option |

Option |

Option |

| Electric Charging |

Option |

Option |

Option |

| Ejectric Injection |

Option |

Option |

Option |

| Accumulator Injection |

Option |

Option |

Option |

| Injection Transducer |

Standard |

Standard |

Standard |

| Nozzle Transducer |

Option |

Option |

Option |

| Screw Speed Display |

Standard |

Standard |

Standard |

| Feeding Mould Temp. Auto Controlled |

Option |

Option |

Option |

| Ceramic Heater |

Standard |

Standard |

Standard |

| Infrared Heating |

Option |

Option |

Option |

| Fan Cooler |

Option |

Option |

Option |

| Auto Material Cleaning |

Standard |

Standard |

Standard |

| Cold Start Protection |

Standard |

Standard |

Standard |

| Nozzle Cover |

Standard |

Standard |

Standard |

| Proportion Back Pressure |

Option |

Option |

Option |

| Servo Valve Device |

Option |

Option |

Option |

| Clamping Unit |

| T-Slot Mold Plate |

Standard |

Standard |

Standard |

| Magnet Mold Plate |

Option |

Option |

Option |

| Mold Size Bigger |

Option |

Option |

Option |

| Mechanical&Electrical Safety Device |

Standard |

Standard |

Standard |

| Clamping, Eject Transducer |

Standard |

Standard |

Standard |

| Product Slide with Photo Cell |

Option |

No |

No |

| Product QS Function Device |

Option |

No |

No |

| Mold Adjustment Limited Switch |

Standard |

Standard |

Standard |

| Auto Mold Adjustment Function |

Standard |

Standard |

Standard |

| Clamping Force Display |

Option |

Option |

Option |

| Clamping Force Control Close-Loop |

Option |

Option |

Option |

| Widen Safety Door |

Option |

Option |

Option |

| Auto Safety Door |

Option |

Option |

Standard |

| Mold Lifting Hanger |

Option |

No |

No |

| Quantitative Centralized Lubrication Device |

Standard |

Standard |

Standard |

| Glass Tube Cooling Flowmeter |

Option |

Option |

Option |

| Quick Plug Distributor |

Standard |

Standard |

Standard |

| Air Valve (1 Unit) |

Option |

Standard |

Standard |

| Core Pulling (2 Units from 500Ton, 4 Units from 1250Ton) |

Standard |

Standard |

Standard |

| Electic&Hydraulic Unscrew Device |

Option |

Option |

Option |

| Unscrewing Counter Sensor |

Option |

Option |

Option |

| Mold Open&Closed Proportional Valve |

Option |

Option |

Option |

| Synchronous Action (Ejector, Core Pulling) |

Option |

Option |

Standard |

| Hot Runner Nozzle Hydraulic Control Function |

Option |

Option |

Option |

| Thermal Baffle |

Option |

Option |

Option |

| Hydraulic Uint |

| SVP Servo Motor/Pump Control System |

Standard |

Standard |

Standard |

| Self-Sealing Magnetic Oil Sucking Filter |

Standard |

Standard |

Standard |

| Pump/Motor Power Increase |

Option |

Option |

Option |

| Cooler Increase |

Option |

Option |

Option |

| Oil Temperature Display |

Standard |

Standard |

Standard |

| Oil Temp. Auto Control |

Option |

Option |

Option |

| Oil Level Alarm |

Option |

Option |

Option |

| Oil Temp. Pre-Heating Function |

Option |

Option |

Option |

| Oil Tank Magnet |

Standard |

Standard |

Standard |

| High Pressure On-Line Filter |

Option |

Option |

Option |

| Low Presure Return Filter |

Option |

Option |

Option |

| Injection Unit |

| 8 Inch Color Display |

Standard |

Standard |

Option |

| 12 Inch Color Display |

Option |

Option |

Standard |

| Action Monitoring Function |

Standard |

Standard |

Standard |

| Producing Monitoring Function |

Standard |

Standard |

Standard |

| Error Alarm Display |

Standard |

Standard |

Standard |

| Hardware Input Output Function |

Standard |

Standard |

Standard |

| Euromap 12 Robot Interface |

Option |

Option |

Option |

| Euromap 67 Robot Interface |

Option |

Option |

Option |

| 3 Colors Alarm Light |

Standard |

Standard |

Standard |

| Rear Safety Door Emergency Button |

Standard |

Standard |

Standard |

| SSR for Heating |

Standard |

Standard |

Standard |

| 3Phase-5Line Socket (16A) |

Standard |

Option |

No |

| 3Phase-5Line Socket (32A) |

Option |

Standard |

Standard |

| Single Phase Socket (10A) |

Standard |

Standard |

Standard |

| European 3Phase-5Line Socket (16A) |

Option |

Option |

No |

| European 3Phase-5Line Socket (32A) |

Option |

Option |

Option |

| European Single Phase Socket (10A) |

Option |

Option |

Option |

| Hot Runner Control System and Interface |

Option |

Option |

Option |

| Internet Manage System |

Option |

Option |

Option |

| Accessories Unit |

| Nomal Hopper |

Standard |

Standard |

Standard |

| Lever Pad, Operation Manual |

Standard |

Standard |

Standard |

| Tool Box, Damageable Spare Part |

Standard |

Standard |

Standard |

| Mold Clamping Board |

Standard |

Standard |

Standard |

| Stainless Steel Hopper |

Option |

Option |

Option |

| Hopper Dryer |

Option |

Option |

Option |

| Hopper Magnet |

Option |

Option |

Option |

| Special Color |

Option |

Option |

Option |

| Robot |

Option |

Option |

Option |

| Water Chiller |

Option |

Option |

Option |

| Mold Temperature Controller (MTC) |

Option |

Option |

Option |

| Dehumidifier |

Option |

Option |

Option |

| Autoloader |

Option |

Option |

Option |

| Fumigated Wooden Package |

Option |

Option |

Option |

| Products Taking Plate |

Option |

Option |

Option |

| Mold cooling:6 ways loop (less 230Ton), 8 ways loop (270Ton-400Ton),

10 ways loop (500Ton-950Ton), 12 ways loop (1250Ton-1850Ton) |